Dear Mr Speedcult and other friends

When considering blade construction and especially

in larger sizes it is advisable to consider other

options - and as you correctly suggest the steel spar

system is a good option for the those who wish a larger

rotor with minimal operational risk and likewise with a

relative easier construction.

I have many times on this board emphasied the good work

done in this respect by Prof Horst Crome from The

Technical University in Bremen.

"Handbuch Windenergie Technik" - by Prof. Horst Crome

available from - http://www.oekobuch.de - is possibly

only marginally bested by Hugh Piggott's series of books

and manuals.

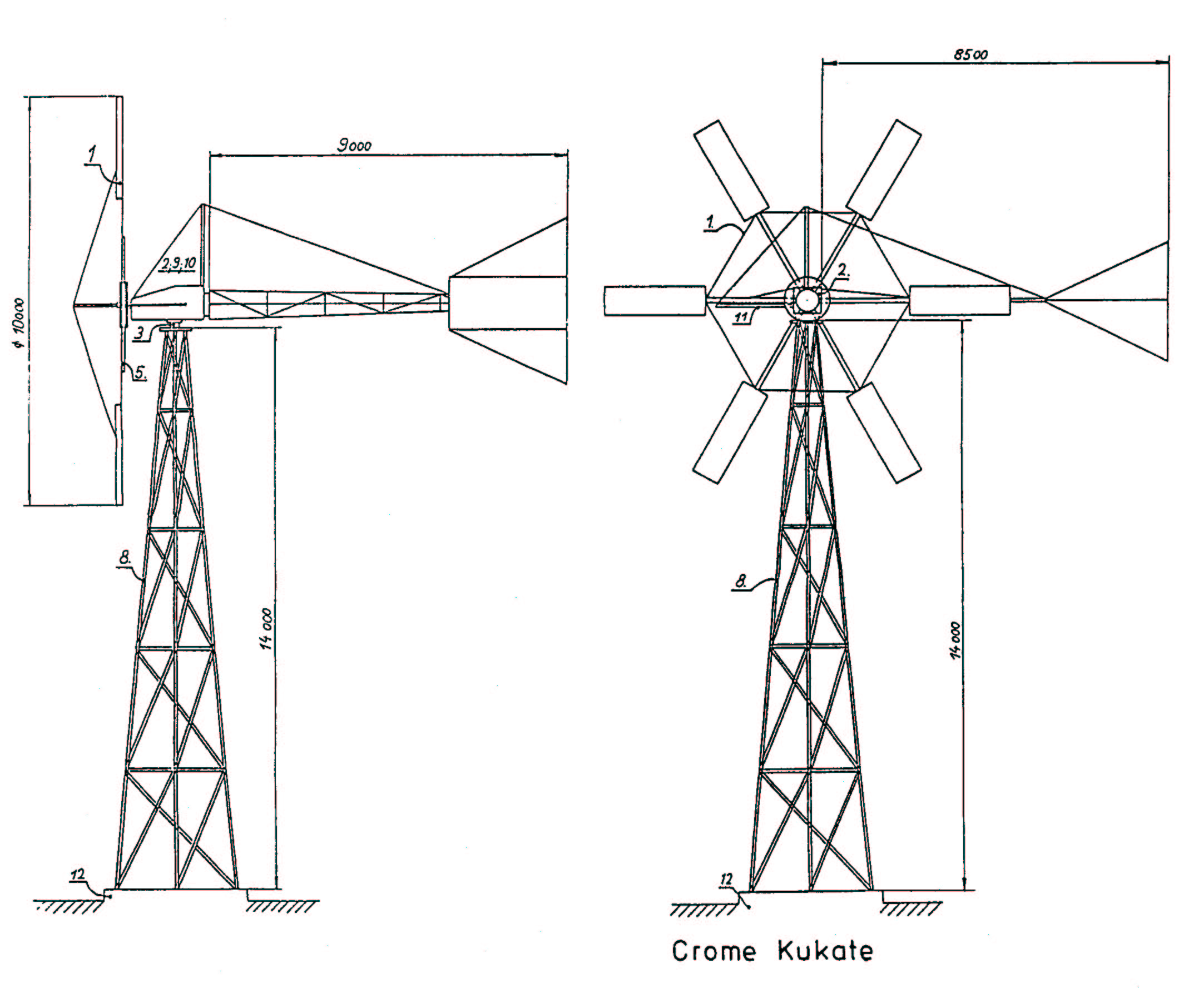

1: I enclose an illustration of the Crome "KUKATE" tower

and rotor construction - please note the use of a side

overspeed-vane

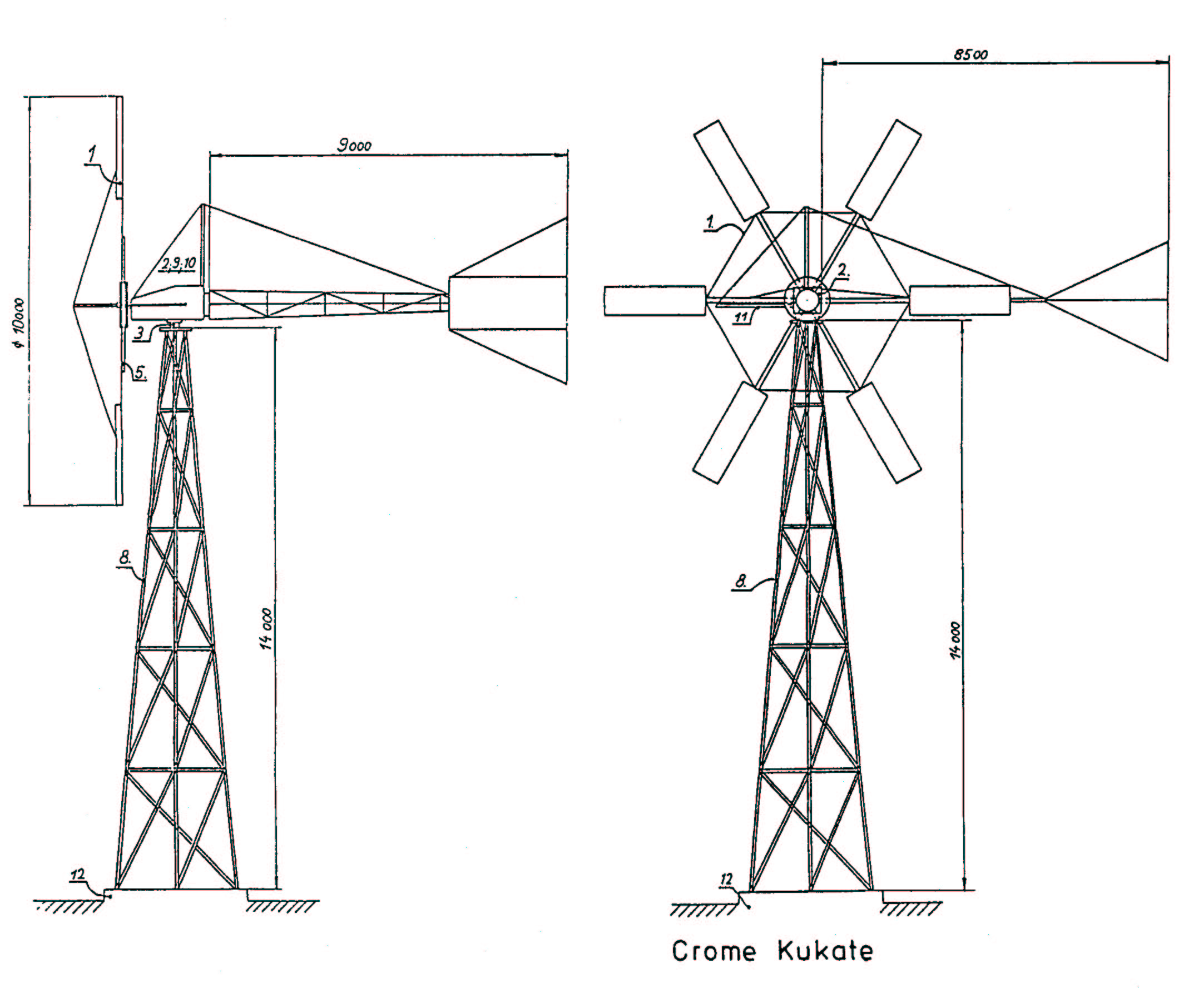

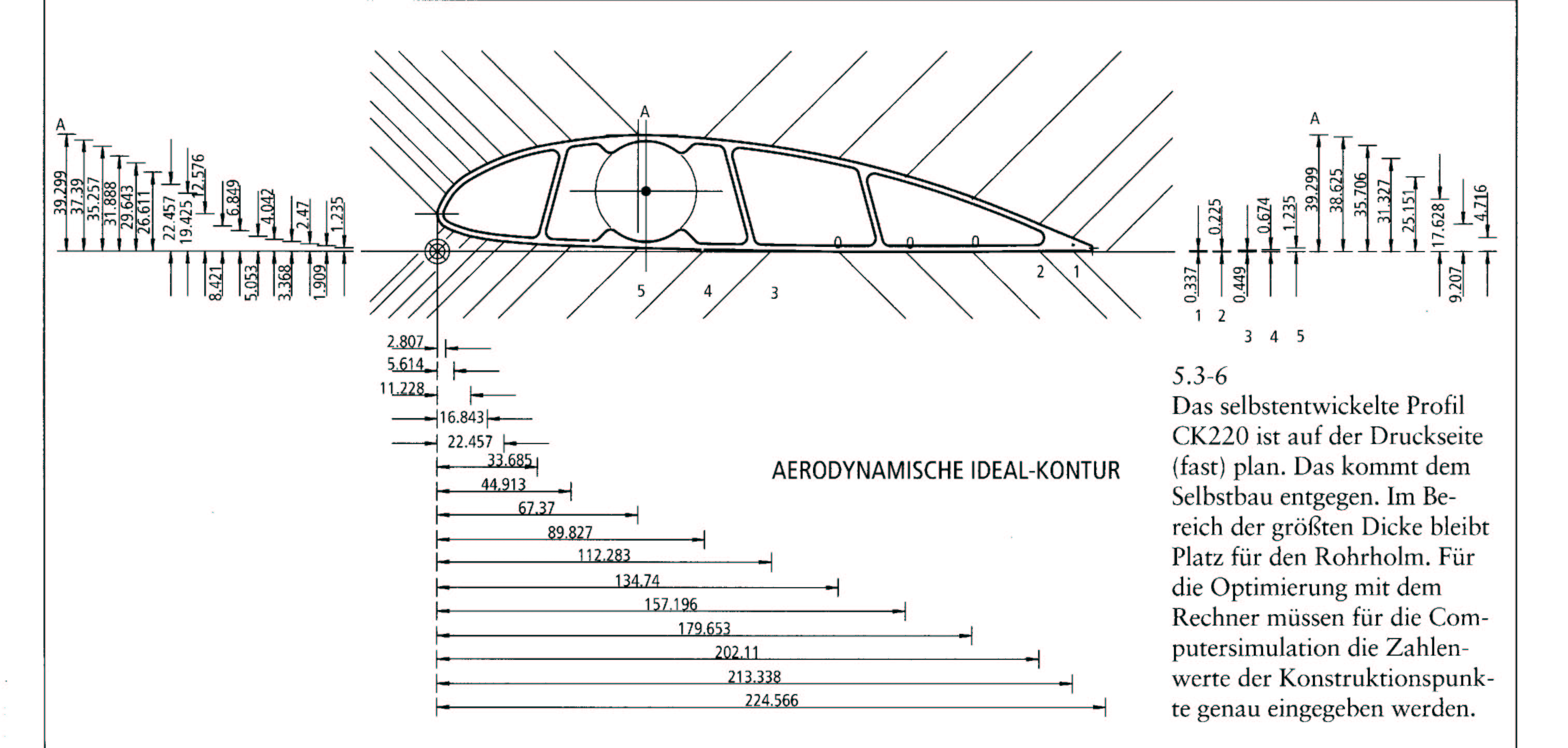

2: This shows the profile and construction of the GOE 624

aerofoil.

Please note the usual traditional method of construction

with a 4mm marine-plywood covering and wooden leading and

trailing edges.

Likewise please note the round steel spar.

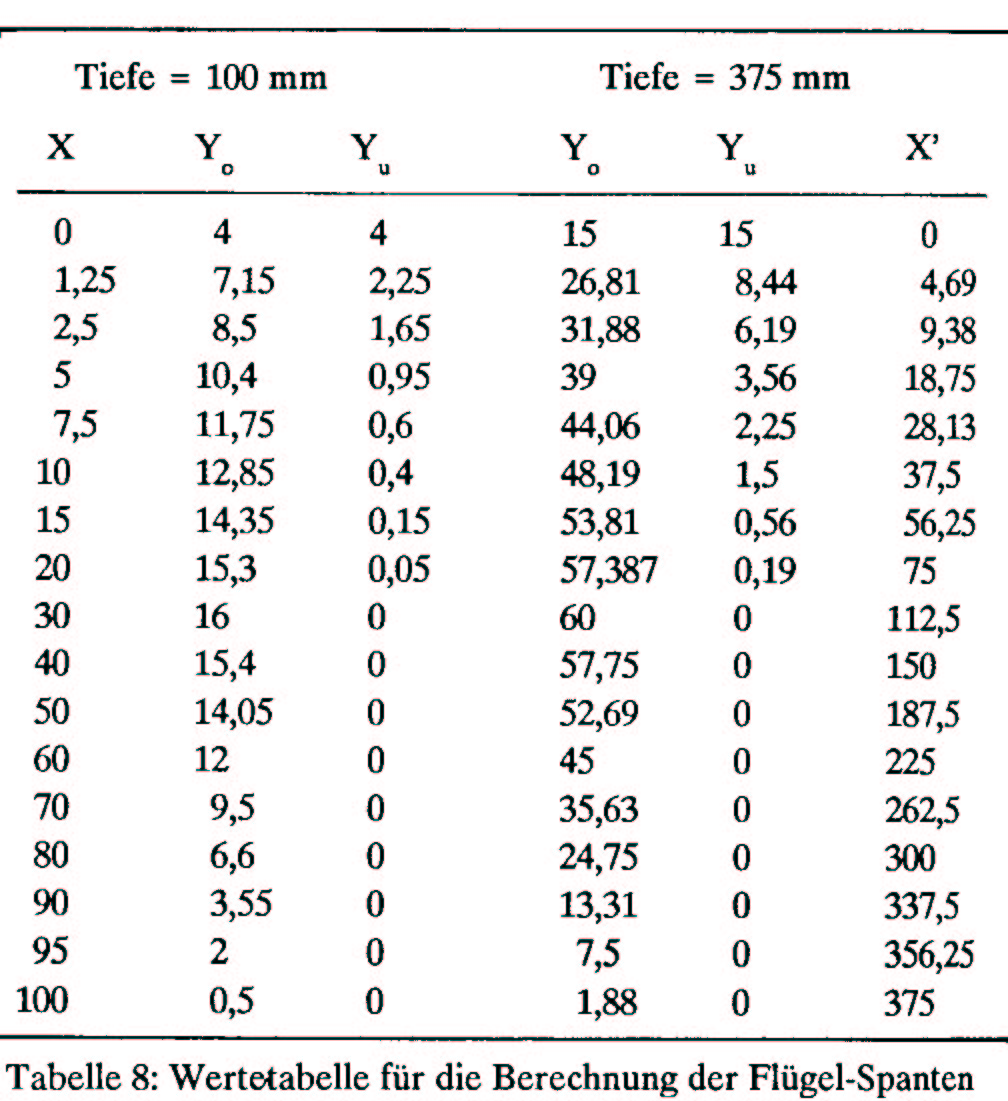

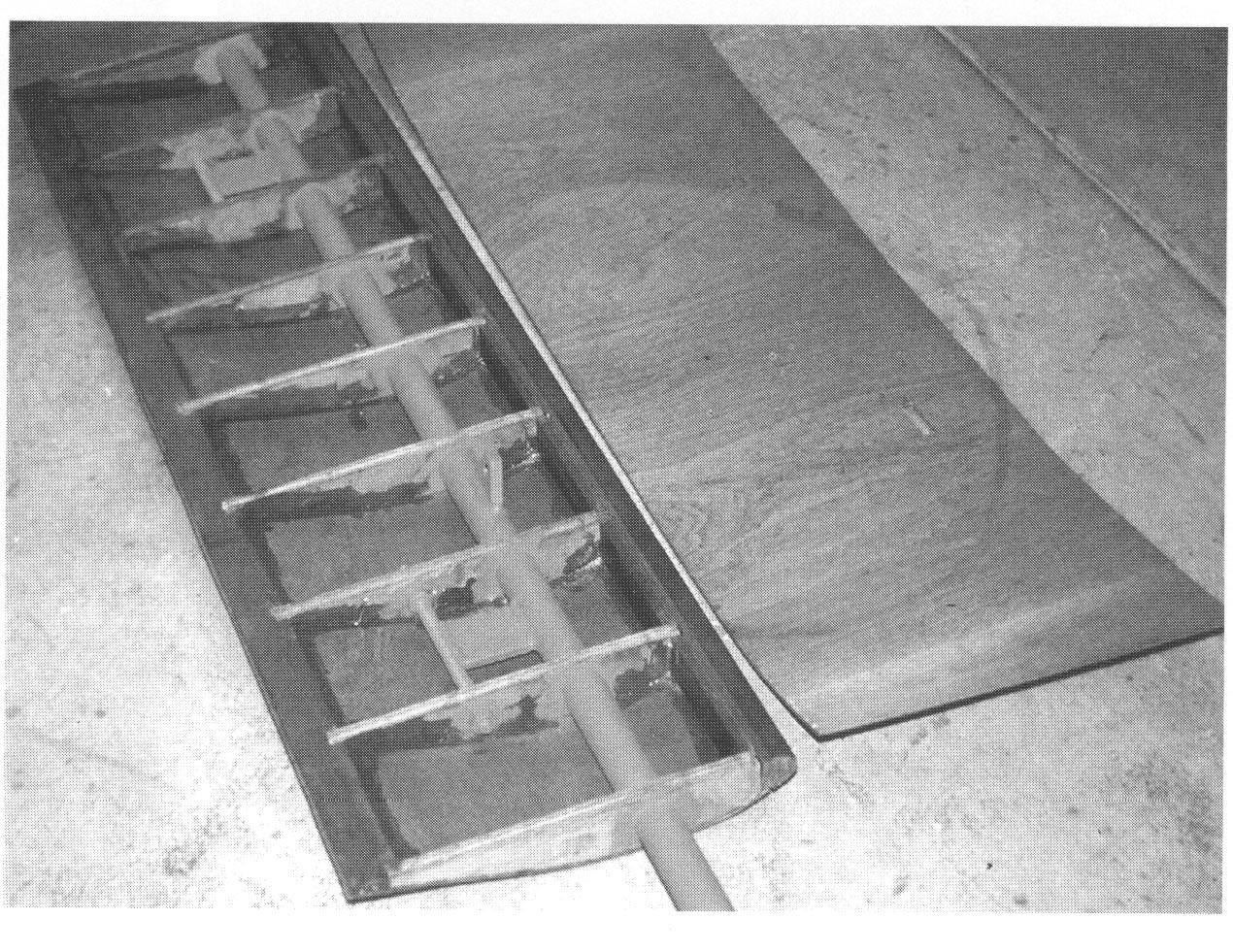

3: This shows another illustration of the blade construction

- please note the two small plates welded to the blade spar.

It will be noticed that a section of allthread is passed

through two aerofoil sections to prevent movement of the blade

itself.

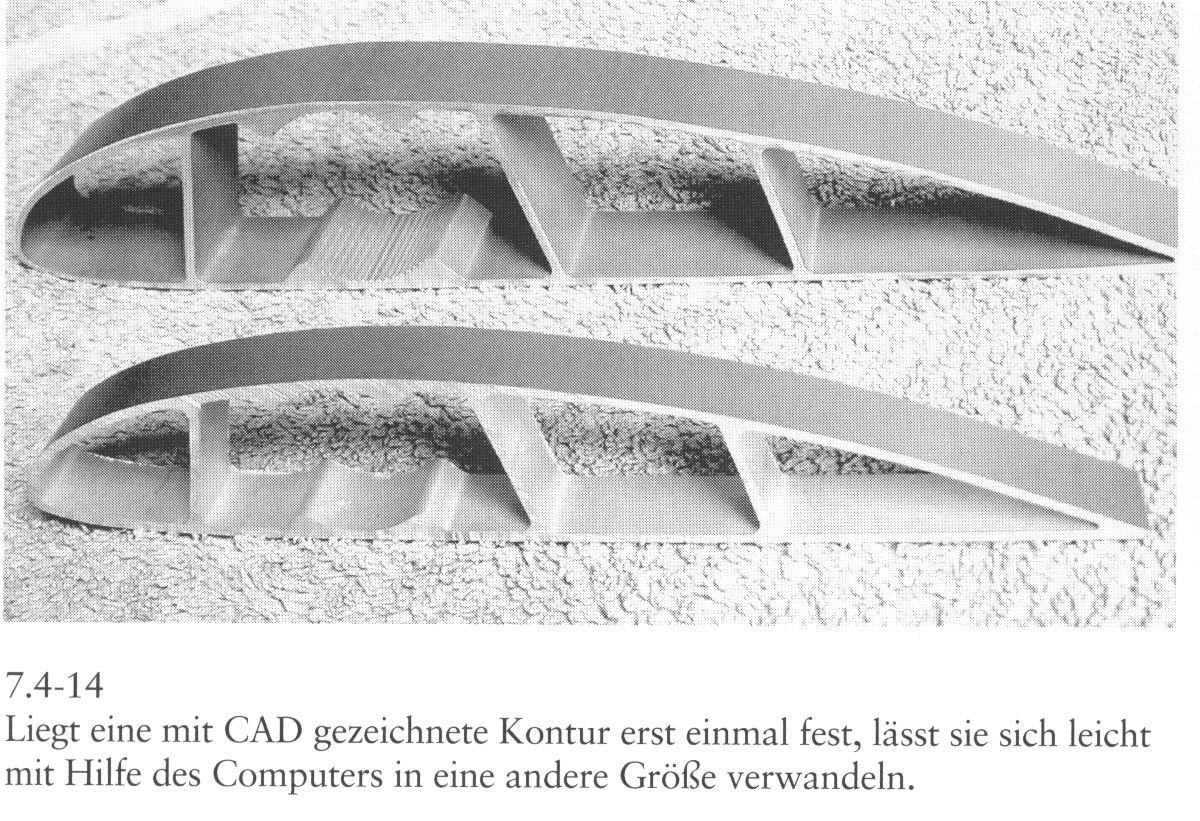

4: A more advanced aerofoil section is as follows:

Please note the use of alumimium aerofoil profiles -

these are either in profile sections or as longer extruded

blades - screwed directly onto the steel spars. It can be

noticed on the first image that the stress forces on the

blades are relieved by the use of stays.

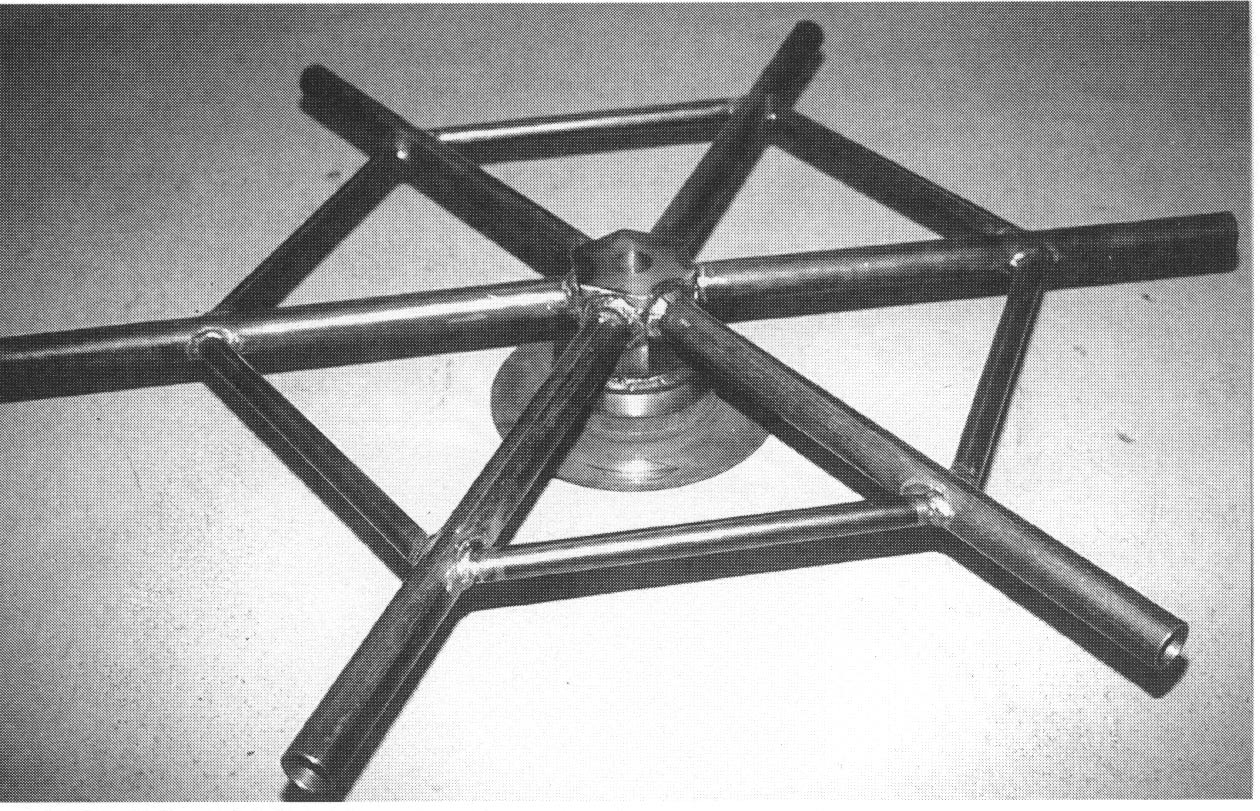

5: Likewise the mounting of the spars or rotor arms can be

made using the traditional hub construction

6: - I have also followed the discussion concerning the use

of alumimum extruded or covered blades -

As for me personally I have no definate position on this

matter at all and am fully aware of the known problems with

this material However - and for the record - I will remark

that in Michael Hacklemann's good book -

"The Home-built Wind-generated Electricity Handbook" -

Earthmind/Peace Press USA 1975

- concerning the re-conditioning and re-building of WINCHARGER

and JACOBS rural power-systems [with up to 1.5 kW units]

from the 1930's and 1940's - of which the 4-bladed WINCHARGER's

utilized alumimium blades - no dire warnings or serious comments

are made concerning the use of this material [page 31].

I can only suggest that the unusal longlivity of these blades

is possibly due to their efficient blade-angle governing-system.

With best wishes to all - JF