Hi Guys time for an update on the Audi gen.

I left off last time having just completed the mechanical build so this is mostly the electrical side of things. It has taken a bit longer than expected as I have been tied up with other things.

First off all calculations and formula where taken from Motors as generators for micro hydo power by Nigel Smith

The Motor I used is a Dutchi 15kw from the "book" it says to de-rate the motor when run as a generator to 80% so that brings us down to 12kw max output but to be honest I don't expect to get that, anyway here is a pic of the plate

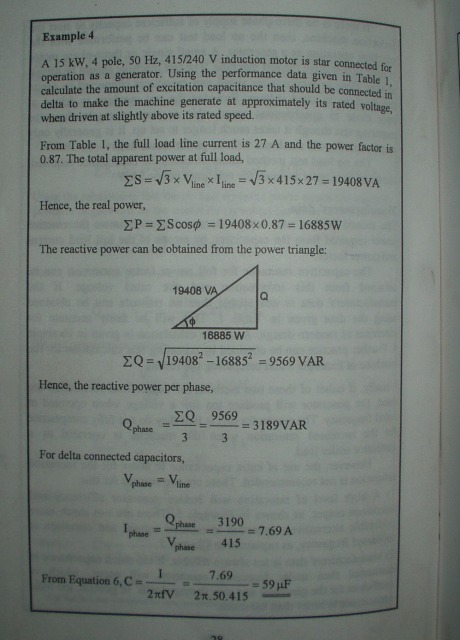

I was just about to work out the formula for calculating the required capacitance when I noticed that one of the worked examples was for a 15kw motor, what a stroke of luck! that saved a page of calculations and a whole lot of head scratching. For those that have the book it is on page 28. The recommended capacitance for excitation is 59uf I have a selection of motor run caps mostly 10 - 50 uf so the closest I could get to was 60uf.

This how the capacitance is worked out.

(NOTE TO ED If this pic causes a breach of copyright just pull it and I will repost I have no idea how to type the symbols for this lol.)

For my first test I connected the motor terminals in star and the caps where then connected across these in delta. I started the engine and started to raise the engine speed while watching a meter connected to phases. From idle at 900 rpm I see 1 volt as you raise the speed the voltage climbs steeply and at a little over 1500 rpm I am getting 400v at 50hz. If you continue to increase engine speed the voltage continues to climb

So that part seems to be working fine

Now 400v out is all very well but I need to charge batteries as well as run 3 phase tools. So I need to step this down to at least 220. There seems to be a few ways to achieve this

- modify the windings of the motor by putting the coils of each phase in parallel (if in series)

- Find a 3 phase 415 -220 transformer and then step down with another transformer set to charging voltage {48v battery)

The 2nd solution looks expensive

I was thinking this over when I had a thought, I have an old 3 phase/single phase oil cooled welder it is a Pickhill Bantam with 2 output ranges 180 amps at 50v and 130 amps at 80v. So with the motor connected star and the caps in delta I connected the welder for 3 phase 415v input and started her up I increased the engine speed but it would not excite! Hmmm time for a cup of tea and a think.

Round two

I disconnected the motor and caps had another read at the book and decided to try it again but rigged for single phase. I connected the motor in delta with the caps in C-2C for single phase and connected the load across 1C as per the book, I then connected the welder for 415v single phase and selected the 50v high current range. I started the engine and brought it up to 1500 rpm where the welder came to life and I was able to weld some hefty plate for about 10 mins. The welder and the motor remained stone cold so I think I have the direction of rotation correct for C-2C as apparently it gets hot quickly if not. I must buy a sequence tester just to check.

Now I think I am getting there!

The 50v range turns out to be 55v at 415 in, so when this is rectified we are in the ballpark for charging the 48v bank. Now for a real test, I connected the output from the welder to 2 large bridge rectifiers from a 72v forklift charger and connected to the battery via fuse and ammeter. I started her up and brought the weld current up 1 notch at a time to the max where I was getting about 40 amps(2kw) I then brought the revs up slightly to about 1600 rpm and 450v at 60hz this increased the charge to about 80 amps. I let it run for about an hour while keeping a close eye on it and it performed well the welder got warm but not hot and the motor was cool . At this point while testing with a volt meter I noticed that when I measure across the two unused phase connections on the welder I was getting 220v so as a quick experiment I connected a 24v 60A charger to charge my 24v bank at the same time. I ran it for another hour charging both banks while monitoring the temperature, both the welder and charger ran warm but not hot and the motor remains almost cold.

Now I know what I have done here is not ideal but it does seem to work with a total of about 5kw. I could easily push for more out of the welder by increasing the speed and thus the voltage as I have seen 700v output with out load but I don't know how that would affect the welder? I don't want to burn it out, I also have this picture in my mind of a fly on a zapper! Only I am the fly.

I would like to be able to run it as 3 phase rather than the C-2C single phase setup but it just refuses to excite with all 3 phases connected, if I remove 1 phase it excites and generates on 2, should I add more capacitance or should I add capacitance to the load?

If I can get a 3 phase transformer 415v 220v would it cause the same problem or does the welder have a large inductor in it that is causing the collapse or is it simply to large of a load

Any suggestions on the best way forward would be most welcome!

Since the last diary entry I have also managed to get the chassis painted and looking a bit prettier, it is now bolted down in its new home and connected to a decent size fuel tank. I have also been playing with different fuels and blends. When running on diesel starting is instant, with no need for the glow plugs to preheat. Next up was waste engine oil filtered to one micron and preheated to about 90c just before the injector pump. Starting from cold takes about 3 seconds with a little bit of smoke on starting but clears very quickly and no visible smoke at working temp of 80c. Next was the waste veggie oil again filtered to 1 micron and preheated the same as the waste eng oil with the same results. No doubt if this was repeated on a car with straight oil there would probably be some smoke or hesitation on acceleration but as the generator will run at a constant speed I don't think it will be an issue. It will be interesting to see how well it starts when winter sets in. Fuel consumption so far is about 1.5 litres per hour, not that it matters as my fuel is free and the noise level is way down compared to the little Lister Petter I used previously.

To sum up

Have I achieved my goal.. well it sort of works if I could over come the collapse of excitation current and run 3 phase I think it would be better but 5kw isn't to bad. The multi fuel engine has worked a treat and although I haven't started with the recovery of heat yet, I don't foresee to many problems. So all in all I am pleased with the results and think it was well worth the effort. Total cost of build so far is under £75 ($150) Total value of sticking two fingers up at the Electricity Company... Priceless

So that's it so far warts and all! Any ideas or suggestions would be very welcome, is there a better way to do this?

Many thanks in advance

Russell