The tower construction turned out to be a feat onto itself. Assembly of tower was done deliberately slow and methodical. Safety is a priority, serious injury could occur if anything went wrong. Walk around inspections, with two people, were performed before any lifts.

Ahead of time, my Father had the anchors and base plate in place. They were well laid out. The left and right anchors aligned straight through the base centerline on the same plane. This was accomplished by shooting the elevation using a transit and tight strings. The anchors are set in approximately 4' deep in a 3'x3' pad of concrete.

The tower is made using 4.25" scheduled 10 galvanized pipe. Below is the gin pole and first section of pipe rigged.

Guyed wires were attached to the first tower section and the gin pole tackle put into place. The gin pole tackle consist of four pulleys. At this stage the tower section was leveled, the base plate anchor nuts tighten with the gin pole directly over its anchor, and the gin pole guide ropes tied on. On this initial lift, line slack remained constant; confirming the anchor points were properly placed.

Note: A good pair of cable cutters are really helpful. Chiseled cut the cable once, then borrowed a pair of cutters from a friend.

Next the pipes were sectioned together using coupling inserts and guy wires clamped on.

No photos were taken while the tower was being raised. All attention was given to the task on hand. It went smoothly without a hitch. The tractor power was kept at nearly idle while pulling.

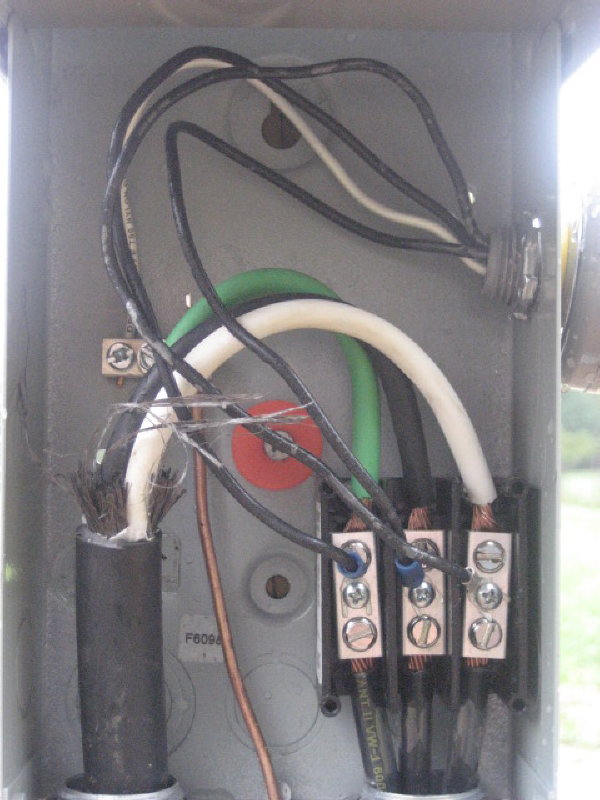

The tower cable is terminated at the base. Three phase is wired to the battery shed via buried conduit. Grounding wire is buried outside the conduit.

Grounding:

The tower is grounded, as well as, each anchor with an eight foot rod driven down beside the concrete. Another rod is at the battery shed. All of the ground rods are connected together to create a "Net". The ground wire is buried approximately two and half feet deep. Two lighting arrestors are installed. One arrestor is on the 3 phase lines, and a second on the DC end.

The tower and turbine were put to the test early. The afternoon following the turbine was in the air, a cold front came through with reported 30 to 40 mph gust.

The turbine would hold between 200 and 300 watts in the winds before furling. Once the turbine was completely furled, the output dropped off to nothing. I did observe a few momentary spikes as high as 600 watts.

Base on feed back on a previous entry, a different tail was made which was lighter. The thrust force to yaw the rotor was reduced to 18 lbs. I'm fairly confident the stator will easily hold up at the present tail weight. In the future will be upgrading the battery bank. As of now, when the wattage goes above 150 watts, the voltage increased enough for the diversion control to begin dumping. So I don't see the sense of capturing more power just to dump it.

Blade noise could only be heard when a large gust came along and the turbine yawed quickly to furl. The alternator makes a slight low tone humming when the output increases, but nothing I consider distracting.

Braking was not a problem. The blade stopped quickly with just two phases shorted out.

I would like to thank everyone on this forum that I was able to learn from and draw information. Especially those who took time to answer questions; the first being defining "Two-in-Hand".

The deer like the new wind turbine too.