Hello everyone,

I've spent the last couple of weeks assembling the tower for my windmill (and I have the mosquito bites to prove it!)

I opted for the 3" pipe, tilt-up type, 45 feet tall. The lowest section is 3" pipe, the next section is 2.5" pipe, and the stub is 2". I made the yawing generator head with 2.5" pipe that I will install once I have the hang if this tower thingy. It is much like the design that is featured on the "how-to" part of this site. Dan hasn't asked me to pay any him royalties yet.

This isn't actually the first time I've raised it - I snuck it up into the air on Sunday for the first time (no kids or dogs around). The weather was quiet when I started, and I set some cable lengths and tensions, but then an electrical storm rolled in, and I decided to put it back down - real quick!

Here you can see the tower on the ground. Not enough pixels for all the guy lines to be visible. The gin pole is fairly long, but I had 20' of 3" pipe sitting around... The upshot is that the tower is very easy to raise: 350 pounds to get it off the ground (measured with a scale), and the load gets smaller, the higher it gets. Also due to the long gin pole length, the weight of the gin balances the tower. I got off the tractor when the tower still had 15 degrees to go, and I pushed it the rest of the way up, by pushing the gin down by hand. It moved gradually and smoothly. Everything came to a stop at the apex without any abrupt wobbling - and presto!

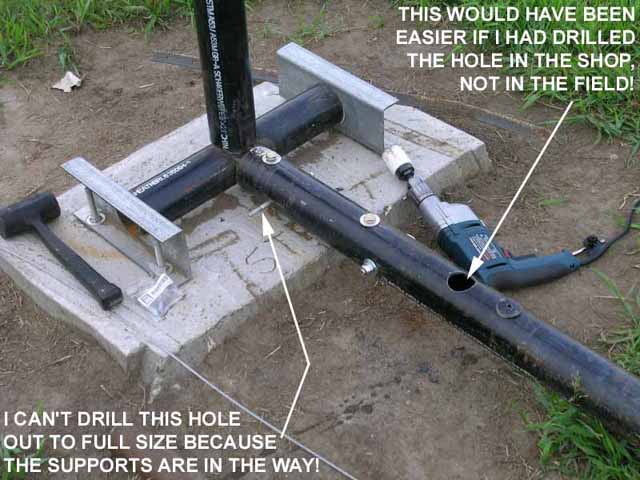

This is where I've made a few errors - nothing catastrophic. I can't drill out one bolt to full size because I can't get the drill between the base supports. How stupid! Also stupid is forgetting to cut a hole in the pipe to let the power cable come out! It's all fixable, but so much easier if I'd done it in the shop!

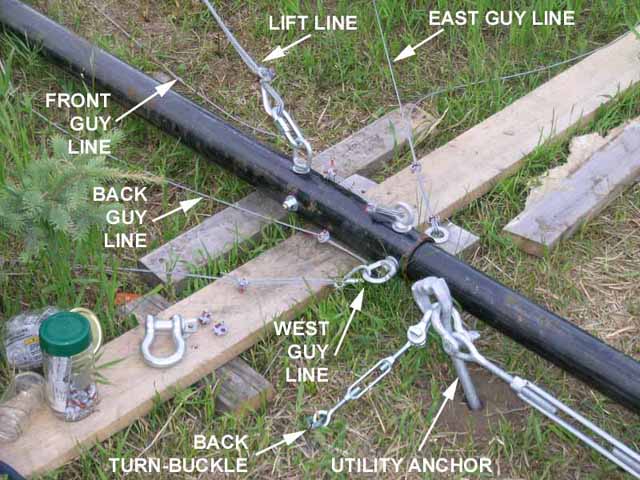

The middle joint is pretty busy. The anchor is 22' from the base, and the first 3" pipe is 21' long, so a lot of cable ends come together in the same spot. The guy wires are small here - they just stabilize the middle of the "noodle". There is also the 3/8" lift cable connected to the gin pole. The tower looks like a soggy noodle if I don't pull it up with a middle lift cable.

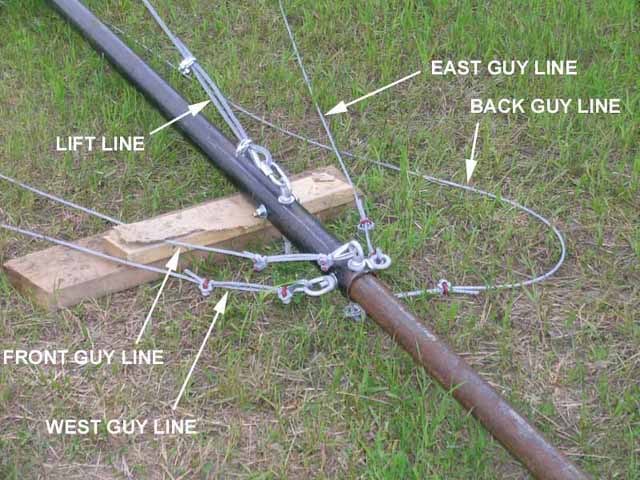

Here's the top set of guy wire attachments. These cables do the real work, so they're 1/4". I opted for eye bolts to make attachments, so there are a lot of multi-purpose fasteners. The eye bolts attach the pipe segments, absorb the bending loads, and connect the guy wire reactions. It sounds like a lot, but there's still lots of margin.

If you've been reading my other postings, you'll see I live in a lightning alley, and I'm going to install lightning protection before I get too far. Some schemes I've read about sound very complicated. I would rather make the tower pipe as well grounded as possible and divert the current from the power wires as early as possible. But these tower joints may prevent that from working...

Steven Fahey