Since I had it available.... I decided to do a conversion on a Baldour 1/2 horse 1725RPM motor. After tinkering with the lakewood box fan, I decided to go for something that might actually provide me with a useable amount of amperage.

The motor as it started out....

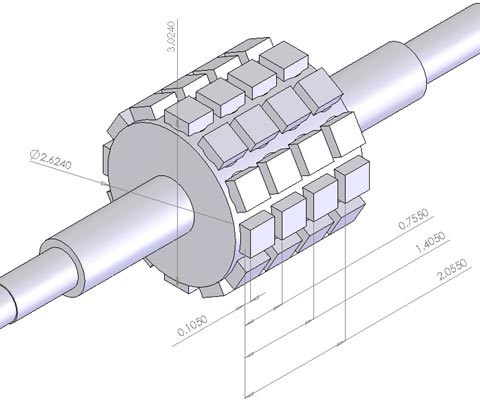

I figured the skew at 5.5 degrees. I haven't yet figured out a way to draw it. What it ended up being was 1.875 degrees between magnets, 5.625 degrees from end to end. Each pole is 3 rows.

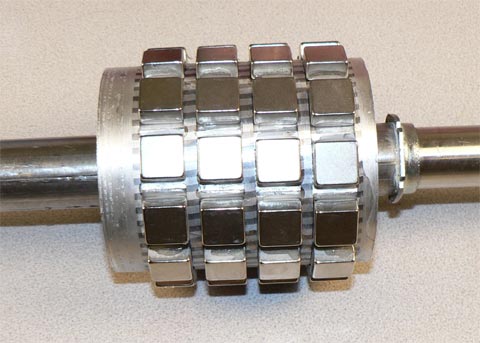

After figuring all the dimensions, the armature was turned down, and milled with 48 flats to mount the magnets. The mags are 1/2" X 1/2" X 1/4"

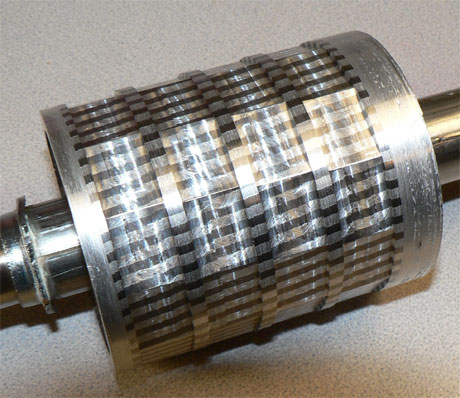

The magnets were mounted with Loctite super glue to hold them while the assembly was poured.

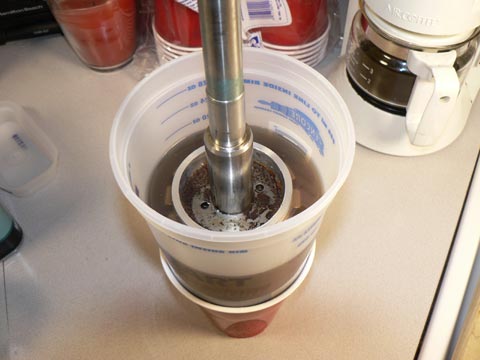

My high tech method of pouring an armature. I find a container slightly larger than the assembly. Poke a hole to let the shaft come through it. Epoxy the face of the armature to the bottom of the container. Pour. Wait. Wait. Wait. Remove. Turn down to size. So far it has worked quite well for me.

When I removed the shaft from the container it was still quite sticky. A pair of 100w light bulbs warmed it up nicely & finished curing.

After it hardened up it went in to work to get turned down to size. I also pressed the bearings on. I couldn't have been happier with how it turned out.

I did remove all of the wiring for the thermal switch & capacitor. This left me with six leads coming out of the can. Wired in star I am seeing 4.5 ohms, 27.5 volts ac at about 180 rpm.

I can turn the shaft with one hand. It does turn a little lumpy, but considering the magnetic field on the shaft (12 lbs pull each X 48 magnets) I am thrilled with how easily it can be turned.

It will soon get a steel hub & a 6' 3 blade rotor.